Nickel 28 Capital Corp.

Suite 5300, TD Bank Tower,

Box 48, 66 Wellington Street West, Toronto, ON M5K 1E6

info@nickel28.com

Overview

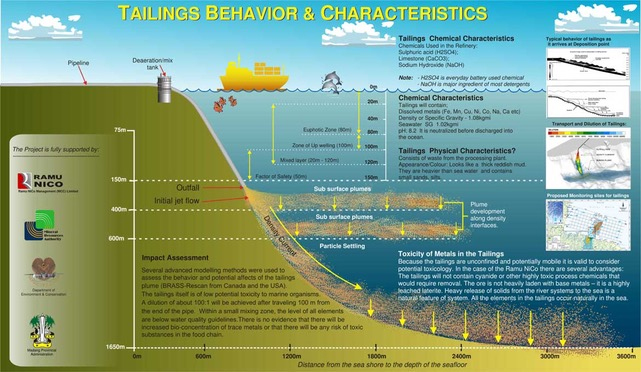

- Following a decade of independent assessment, detailed analysis and permitting, Ramu chose deep sea tailings placement (DSTP) as its preferred method of tailings disposal

- DSTP has a range of technical advantages when compared with on-land tailings dams, especially in Papua New Guinea (PNG)

- Detailed independent assessments have shown that the environmental risk associated with DSTP is significantly less than for an on-land tailings dam

Initial Assessment – 1997 to 1999

- Ramu and independent consultants analyzed 5 alternatives for tailings disposal, including 4 on-land sites for large tailings dams

- Feasibility studies and environmental risk assessments completed for each alternative

- Baseline studies, re-vegetation trials at the mine site and ocean profiling were also completed

- Following the above, an environmental plan (EP) was submitted to PNG government

- EP was peer reviewed by six independent consultants

- Ramu’s Deep sea tailings placement was analyzed against several key criteria

| Criteria | Ramu DSTP site |

|---|---|

| Steep slopes >12% so that tailings flow by gravity into deeper water | Very good – slope of DSTP more than 200 |

| Stable near-shore slopes | Good |

| Deep ocean basin for tailings disposition | Very good – detailed ocean profiling indicates that most tailings will deposit in Vitiaz Basin at depths between 1.0km – 1.6km deep |

| Natural sedimentation in DSTP location | Excellent – High rainfall in PNG deposits 80 million tonnes annually of natural erosion/sedimentation into the Vitiaz Basin, meaning Ramu will contribute less than 6% of the total sedimentation load. High sedimentation also ensures distribution and dilution of the tailings deposits on the seabed will be relatively rapid over life of mine and eventual burial following mine closure. |

| Permanent density gradient to trap tailings below deepest mixing layer of 120m | Excellent – Ramu DSTP outfall to extend to 150m, well below density gradient |

| No strong currents near sea-bed | Good – Peak sea-bed currents measured less than 0.2 m/sec |

| No upwelling current | Excellent – Upwelling currents do not occur below 100m depth. Ramu outfall at 150m. |

Scientific Studies

- PNG government commissioned six (6) independent reviews of Ramu’s EP

- Additional assessments were undertaken to assess the impacts of the tailings disposal and to test the potential toxicity to marine organisms

- A 12-month oceanographic study was completed

- Extensive meteorological data was collected at Ramu’s refinery site

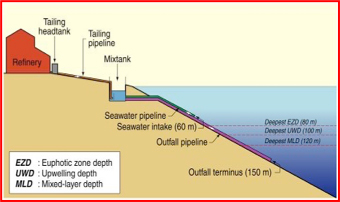

- Results indicated that outflow of tailings should be below 120m, which was the deepest depth at which mixing of solids and potential upwelling could occur. Ramu’s DSTP was designed for discharge at 150m.

- Studies determined that a high level of dilution of tailings material is achieved quickly

- Studies also indicated that the tonnage of tailings material would be a small percentage (less than 6%) of total solids being transported into the Vitiaz Basin by normal erosion, ensuring burial of the tailings deposit relatively quickly following closing

- In addition, there was no evidence that there would be any increased bio-concentration of trace metals or that there would be any risk of toxic substances in the food chain

- Terrestrial and marine baseline survey was completed

- Management and monitoring plan during construction and DSTP operation also prepared

Deep Sea Tailings Placement – Main Features

- Mixing with seawater in a mixing/deaeration tank

- 70m below the deepest sunlight zone (euphotic zone depth)

- 50m below the deepest depth where material could be brought to the surface by water movement (upwelling depth)

- 30m below the deepest depth where surface material mixing could occur due to waves and ocean currents (mixed-layer depth)

- Outfall at 150m in a steep-sided submarine canyon with a slope of more than 200

- Tailings are neutralized to a pH of 8, the same as seawater

- Heavy metal concentrations in tailings are lower than international standards and testing shows metals do not leach into seawater

- The toxicity testing of the Ramu tailings indicated the tailings are nontoxic after proper dilution.

Natural Erosion

- Significant natural erosion of approx. 80 Mt of solids into Vitiaz Basin every year

- Ramu contributes 4-5 Mt of solids into Vitiaz Basin, representing less than 6% of annual deposition

Challenges of Tailings Dams in Pacific Rim

- Significant rainfall (positive rainfall balance – more rainfall than evaporation)

- Soil strength and stability are insufficient to meet safety factors required for best in class standards

- High risk of catastrophic failure due to earthquakes – high seismic activity

- Loss of productive land / culturally significant land

- Topography of coastal PNG makes locations for tailings dams almost impossible in most locations

- Risk of seepage into drinking water sources and productive land

- Significant rehabilitation challenges and costs

Typical Tailings Dam

DSTP Safeguards and Ongoing Monitoring

- DSTP pipeline designed to withstand tensile force of 188 tons, while maximum force caused by a sliding slope undersea is only 14 tons

- All pipeline materials, pumps and valves were manufactured to highest standards and imported from North America and Europe

- Emergency shutoff systems and two 5,000 m3 emergency ponds if spill is detected

- DSTP pipeline is visually inspected annually by an underwater ROV

- Quarterly environmental monitoring reports are prepared for PNG government

- Monitoring reports include:

- Fresh and marine water quality

- Biological tissue analysis for shallow water, reef and deep-water fishes, shell fish and sea grass

- Sedimentation flows and distribution analysis

- Ocean floor sedimentation analysis

- Notification of any significant environmental incidents

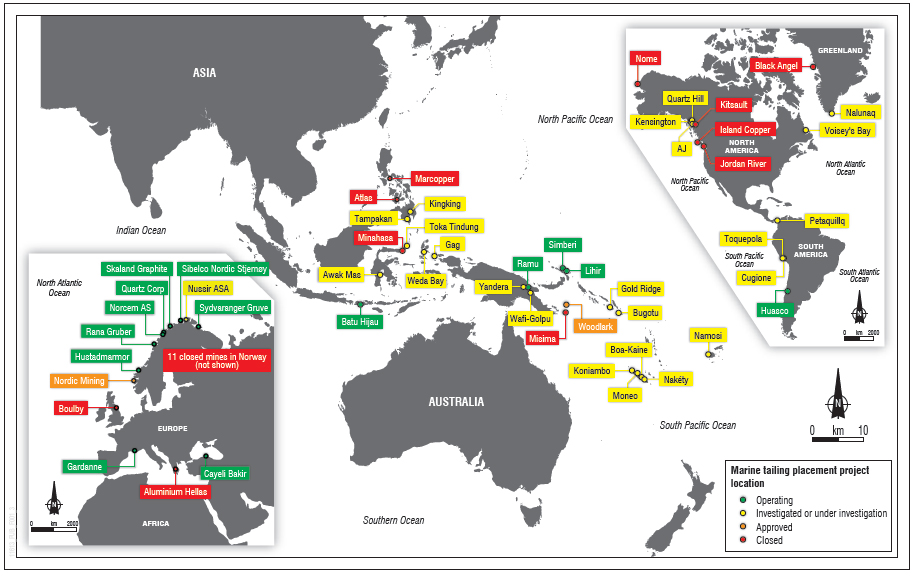

Ramu DSTP Benchmarking

- Ramu ore is highly oxidized laterite rock, meaning it’s low in sulfides and heavy metals

- Ramu combines its slurry residue with limestone to form gypsum

- Ramu DSTP, being gypsum, has a pH of 8, the same as the ocean water

- Most other marine tailings projects are copper/gold mines that process unoxidized ore which is high in sulfides and heavy metals

- These mines generally use cyanide to process the ore and deposit acidic tailings, using seawater to neutralize the tailings

Significant Advantages of Deep Sea Tailings Placement

- Not susceptible to catastrophic failure as has occurred at Ok Tedi in PNG, and in several incidents in Brazil and in Canada

- No risk of seepage from tailings that would contaminate ground water

- Does not occupy productive or culturally significant land

- No need for land reclamation post-closing

- Environmental impacts are limited to very deep water where ecosystems are unproductive, not heavily used and virtually isolated from surface sea water

- Does not impact marine life or species that are in food chain

Deep Sea Tailings Placements Around the World